Address: Xinnan Village,Yaoguan Town,Wujin Dist,Changzhou City,Jiangsu Province,China

Tel: +86 519 8877 1678

Fax: +86 519 8877 4001

Cell: +86 13616125265(Wechat)

E-amil: tube@czchengxin.com

Address: Xinnan Village,Yaoguan Town,Wujin Dist,Changzhou City,Jiangsu Province,China

Tel: +86 519 8877 1678

Fax: +86 519 8877 4001

Cell: +86 13616125265(Wechat)

E-amil: tube@czchengxin.com

Quality control system

1. Quality Management System: GB/T19001-2016 / ISO9001:2015

2. Test&Inspection System:

Control of quality is based on following pionts:

1. Traceability of product: Traceability is based on Heat No. of steel. Inspection of raw material,Mill Test Certificate of raw material,management of stock ensure that we can track each piece of tube we produce and ship.

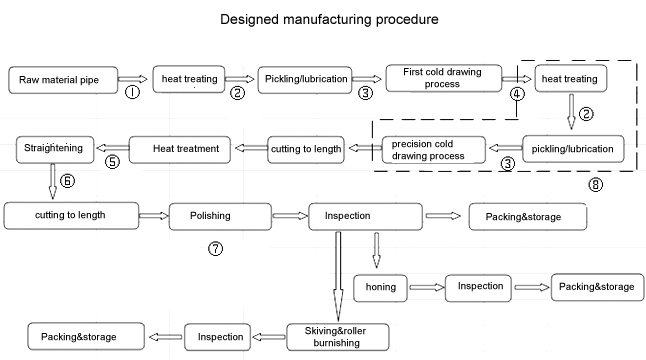

2. Control of production procedure: Before formal production,we make quality control plan covering all production and inspection stages.

3. Control of finished tubes: After production, there will be final overall inspection that ensures all the tubes are strictly in accordance with relevant standard specification and customer’s technical requirements.Based on this, we will issue our Mill Test Certificate to our customers.

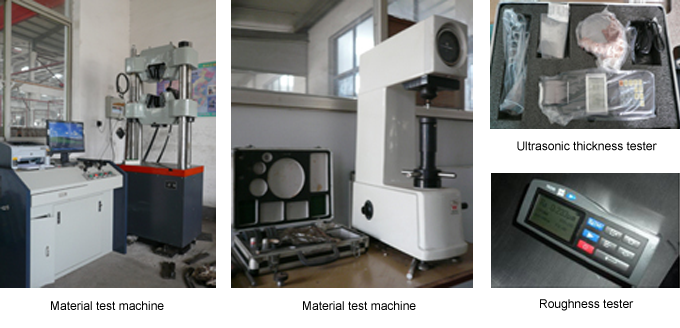

In house inspection: Surface quality,Visual Dimensional Inspection,Hardness Test,Flattening test,Tensile test,C-S analyzer,Roughness test,Non-destructive detection system(Eddy-current+Ultrasonic test).

Third party inspection:

As an important part of quality control system in our company,the inspection range covers general test items like chemical analysis,tensile test,hardness test,and special requirements like impact test,metallographic test,etc. We can accept any world famous third party inspection authorities like SGS,BV,Intertek Moody,etc. Customers can also authorize us to appoint third party inspection authorities and we ensure the qualification of these authorities who are all national certified professional labs in world famous enterprises

like CSR Qishiyan Limited,Changlin Group,etc.

Quality improvement

We are devoting ourselves to improving the oeverall quality of the tubes through introduction of human resources,improvement&input of equipment&device,proceduction procedure,and management.

We ensure stable quality through stablizing the sourcing channel of raw material and strict in house test&inspection system.

Based on stable quality, we adpoted hot phosphating procedure, use high quality alloy steel modules with regulated dialy maintenance, and better packing material to ensure that the tubes are of better internal&external surface quality,more strict size tolerance,better appearance,and under better proection&storage.

①Inspection of raw material pipe: Chemical analysis,surface inspection,Tolerance of W.T:+/-8%, tolerance of OD:+/-0.75%。

②Inspection of pickling and lubrication

③Inspection after cold drawing: size&size tolerance,and internal&external surface.

④Tensile test: tensile strength,yield strength,elongation,hardness,flattening

⑤Inspection of straightness:horizontal straightness by device and vertical straightness by naked eyes.

⑥Polishing&inspection:external surface check.

⑦Second cold drawing:Size&size tolerance,internal&external surface.

Instructions about OD,ID,W.T,straightness of tubes:

1. Tolerance of OD will be as per standard specification,if there no specific requirement. ID tolerance as per customers’ requirements.

2. Ovality of ID: 0.15mm max.

3. Tolerance of W.T: +/-5%

4. Straightness: 0.5mm/1000mm max for tubes below 3m, 0.8mm/1000mm for tubes between 3m and 6m,1.2mm/1000mm for tubes between 6m and 9m